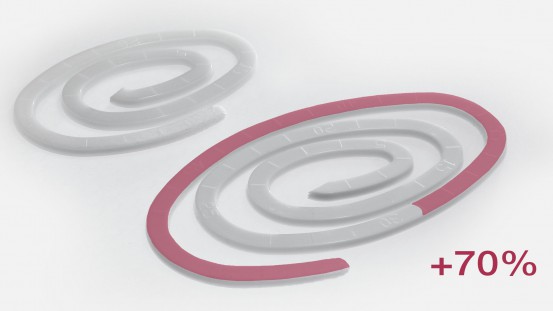

Trials carried out with RJG Technologies, a well-known independent testing laboratory, clearly revealed that BRUGGOLEN® TP-P1810 enabled in excess of 20% cycle time reduction during molding and, significantly, allowed filled compounds containing 50% and more of glass fiber to be injection molded into very intricate and complex shapes. For instance, during molding tests, the flow spiral of a semi-aromatic polyamide reinforced with 50 wt.% glass fiber was lengthened by 70% at a dosing rate of BRUGGOLEN® TP-P1810 of only 1.5%. Much-improved color and appearance of the resultant molded parts are a welcome result of the excellent processing enabled by BRUGGOLEN® TP-P1810. Alternatively, by allowing a 30°C reduction in melt temperature, the additives clear the way to gentler processing and reduced energy consumption.

Dr. Klaus Bergmann, Head of Polymer Additives at Brüggemann: “With the continually tightening emissions regulations we are seeing the pursuit for ever lighter components. BRUGGOLEN® TP-P1810 and BRUGGOLEN® TP-P1507 are key tools to help our customers make this happen.”