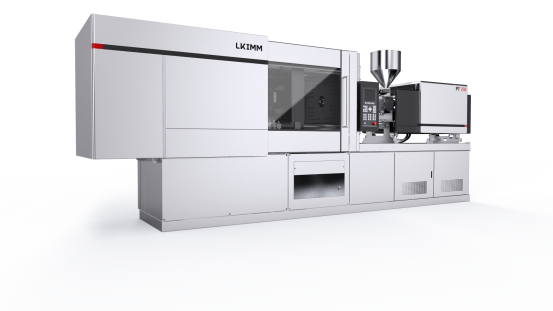

The LK/BKT agreement list those IMMs for which both partners have evaluated most promising sales potential in Europe: e.g., the servo-hydraulic toggle POTENZA (800 to 10,000 kN clamping force), the all-electric ELETTRICA (1,000 to 6,800 kN) or the High-Speed LENA-HS, (2,000 to 4,000 KN) which is particularly suited for mass production of parts for the packaging industry, for medical devices and pharmaceutical components. "By K 2022, we will have further expanded our presence in Europe, following the BKT model, and defined the European sales and service network more closely in order to also intensify business with multinational companies," says Luigi Tondi, Sales & Business Development Director of LK IMM Europe, with registered offices in Travagliato near Brescia, Northern Italy.

Furthermore, the delivery programme offers two-platen machines (FORZA 4,500 to 70,000 kN), multi-component IMMs, type VARIA (1.300 to 20.000 kN), as well as the smaller LENA (500 to 4,000 kN clamping force). With the entire product range, the supplier meets the requirements of the European market for maximum precision "fast and reliable right from the start" and the lowest possible energy consumption as well as an attractive price/performance ratio – especially in the automotive, food & packaging, medical device and pharmaceutical technology, white goods, electrical/electronic, household appliances and toys sectors. In the heavy IMM sector, the economical production of buckets, large containers, transport boxes and pallets play an important role.

The 'Bexte' way to raise customer interest and conclude contracts is "... partnership by competence: to offer long-lasting, reliable, economical products with the highest level of European quality, to guarantee comprehensive service and to respect customer expectations – and to do this in direct dialogue with the designers, manufacturers and suppliers of injection moulding equipment," confirms Andreas Bexte, who has been working in the plastics industry for 34 years. He also supports customers – in cooperation with energy consultants – in taking advantage of subsidy potential. Cross-selling through an expanded range: BKT also represents ancillary equipment from well-known manufacturers: "... so we can build a complete manufacturing cell for a user."

The first KUTENO 2022 day brought another success story: SK Industriemodell GmbH, based in Übach-Palenberg, Germany, ordered its first LK POTENZA injection moulding machine with a clamping force of 1,300 kN on 10 May 2022. Delivery is scheduled for August 2022 - following official acceptance at BKT, Essen. "We decided on this robust, FEA-developed, servo-hydraulic toggle machine with European standard. Among other advantages, it is known for minimal deflection, low mould wear and user-friendly functions," confirms Dipl.-Ing. Sebastian Krell, Managing Director of SK Industriemodell. The 23-member team of experts at this design and engineering service provider – with its own mould making department and eight IMMs – builds its success on profound development know-how for high-quality injection moulded components. The development of prototypes, sometimes on behalf of RWTH Aachen University, and the production of small injection moulded batches for high-quality niche products are part of the core business.

Luigi Tondi, who is responsible for LK Machinery's presence at the K 2022 trade fair from 19 to 26 October at Düsseldorf, Germany, offers a glimpse behind the curtain: "In Hall 13, Stand B45, we will be demonstrating industrially realistic productivity on three newly designed injection moulding machines. The all-electric ELETTRICA, with 1,300 kN clamping force, produces high-precision parts in very short cycle times. A LENA with 3,000 KN demonstrates its advantages in the field of high-speed packaging. The 5,500 kN FORZA will show prospective customers what the new two-platen clamping system offers namely generous space for moulding with minimum space requirements among other benefits."