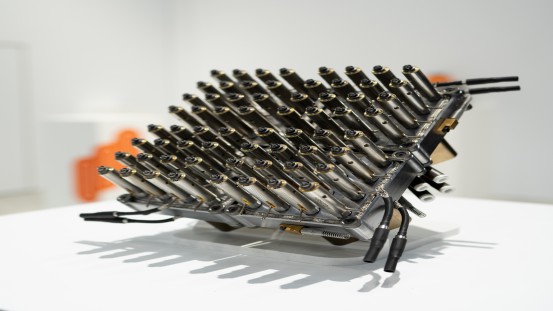

Compact hot runner system – the world's first 3D-printed hot runner system

The new compact hot runner system H4070/... with additively manufactured manifold blocks has been added to HASCO's Multi Shot range.

Maximum quality and efficiency can only be achieved through the intelligent application of creative mould components and the very latest manufacturing technologies. The innovative compact hot runner system H4070/... was showcased for the first time at the recent K plastics fair in Düsseldorf. One special feature of the system is the additively manufactured manifold blocks, which offer completely new possibilities in hot runner technology. Further advantages of this new hot runner technology include minimal spacing and highly variable nozzle layouts with consistently optimum natural balancing.

In the design and construction of injection moulding tools, installation space is particularly valuable. In addition to the proven Multi Shot range, mouldmakers and injection moulders can now also take advantage of the benefits of the compact hot runner system H4070/... The compact system with variable spacing from 18 mm, modified size-20 Techni Shot nozzles and naturally balanced manifold blocks heated on both sides, is supplied fully assembled and ready to install. Leak-free operation is guaranteed. The nozzle tips and heating unit can be mounted or removed from the front, thus facilitating maintenance work. The cable outlets are freely rotatable. Nozzle lengths of up to 125 mm are available. Variable nozzle tips of CuCoBe or TZM as well as individually controllable nozzles and manifolds ensure a highly uniform temperature profile and enable reliable processing of polyolefins and styrenes, as well as many engineering plastics with a narrower processing window.

Apart from the size of the nozzles being reduced to a minimum, the specially developed manifold block contributes to the space efficiency of this compact hot runner system. The printed, naturally balanced manifold block can, through this technology, be kept extremely small and the smooth, material-saving runner makes for a reliable injection moulding process and guarantees high-quality results. A flexible, easy-to-replace tubular heater follows the melt flow very closely, ensures uniform heating of the manifold, and guarantees an overall homogeneous temperature profile.

The compact hot runner system can be used in two variants for single or multiple applications. As a rule, it is provided with a sprue bushing and is thus completely integrated into the mould. Via a hot runner block, as a traverse and a screw-in adapter for assembly below a manifold block, the system allows the grouping of mould cavities in clusters. Through this modular design, it is possible to dispense with a solution of complex manifold blocks and allows, as shown here, a 64-point system with external dimensions of only 220 x 220 mm.