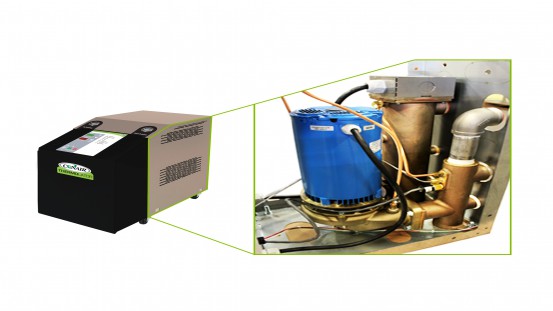

The new product feature includes a cast-bronze pump volute, heater tube, mixing tube, and impeller. The combination is designed to deliver longer working life than previous corrosion-resistant Thermolator TCU products, explains Jim Fisher, Conair’s Sales Manager, Heat Transfer. “Thermolator TCUs with non-ferrous construction are a great solution for processors who are using distilled or RO (reverse osmosis) water, both of which can be aggressive to iron components, and who want to reduce corrosion levels in their process cooling systems. Medical molders and others can benefit from this design.”

The Conair Group (www.conairgroup.com) is a leading global supplier of auxiliary equipment for plastics processors, including resin drying systems, blenders, feeders and material-conveying systems, temperature-control equipment and granulators. Extrusion solutions include line-control systems, film and sheet scrap-reclaim systems and downstream equipment for pipe and profile extrusion. Over 450 individual products solve problems, save energy, cut waste and are easy to use. Conair is also an international company, with long-standing operations in Europe, Asia and Latin America. The industry’s most complete product line, top-flight engineering and unbeatable service, all combine to give processors the confidence they need to succeed in today’s competitive global marketplace.