Companies requiring complex components that meet the highest demands can’t afford to miss the DIEFFENBACHER stand (hall 5, stand R42) at JEC World 2020 in Paris, March 3-5. DIEFFENBACHER offers fully automated, highly productive and cost-efficient production lines for applications in the automotive and transportation, building and construction, aerospace and sports and leisure sectors.

Automated SMC systems from DIEFFENBACHER are used to produce highly complex SMC components profitably and with consistently high quality. The systems, anchored by a press from the Fiberpress series, are also characterized by equally high availability and output rates.

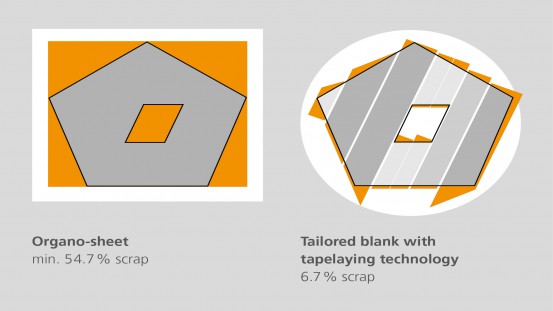

With the Tailored Blank Line, consisting of the Fiberforge tape laying system and the Fibercon consolidation unit, customers can produce more than one million components per year. DIEFFENBACHER’s Tailored Blank technology is the clever and economical alternative to organo sheets. It offers flexibility in the use of materials and causes significantly less scrap due to the precise, load-oriented and near-net-shape laying of tapes.

DIEFFENBACHER Fiberpress

In cooperation with Arburg, DIEFFENBACHER offers customers an additional option for producing components with complex geometries. The combination of a DIEFFENBACHER vertical press with a bolt-on injection molding unit from Arburg creates a highly flexible production system for a wide range of applications in the automotive and aerospace industries, among others. It enables the processing and back injection molding of reinforcements made from continuously reinforced thermoplastics (e.g., PP, PA, PEEK) and offers the necessary precision to produce complex, thin-walled components with hybrid structures. The bolt-on unit is easily coupled to and uncoupled from the tool. In contrast to an injection molding machine, the press achieves very low component thickness tolerances and can be used for other production processes (e.g., SMC and thermoforming).

In addition to solutions for tape laying, SMC, LFT-D and wet molding technologies, DIEFFENBACHER will present its MyMessenger messaging and ticket system app. The app helps personnel communicate with each other within the system to solve problems and to report service cases quickly and directly to DIEFFENBACHER for real-time assistance. A major advantage: Both sides can write in their native language; MyMessenger takes care of the translation.

Innovative ideas and solutions for recycling composite components complete DIEFFENBACHER’s presence at the trade fair. Concepts ranging from shredding through cleaning to the production of new end products made from recycled materials (Waste 2 Product) will be presented. Individual turnkey production plants for applications such as flooring, transport pallets and sheet products help customers to reduce disposal costs and manufacture their products in a sustainable and resource-conserving way.

Tailored Blank Line, consisting of Fiberforge (right) and Fibercon (left).

For DIEFFENBACHER, the exchange with customers doesn’t end with the acceptance phase. The company maintains a partnership-based relationship with customers, ensuring that high-quality support and advice are always available. That’s one reason that companies such as Audi, BMW, Autoneum, Fritzmeier, Hanwha and Polytec continue to rely on DIEFFENBACHER’s advanced technologies.