For more than 30 years, Sumitomo Bakelite Co., Ltd. has sustained a leading global position in the supply of semiconductor encapsulation materials that are used extensively in IT equipment such as PC’s, smartphones, tablets, and servers. Due to the recent rapid adoption of electric (EV) and hybrid (HV) vehicles, coupled with increasingly complex IT systems in new mobility solutions, the company is now expanding their production capacity to meet the increasing demand for epoxy encapsulation materials in automotive applications.

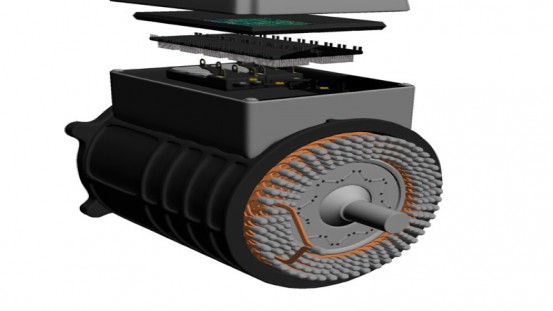

The Sumitomo Bakelite Co., Ltd. epoxy encapsulation portfolio covers a wide array of e Drive applications such as high speed permanent magnet rotors, stator insulation and coil impregnation.

These all contribute to increased efficiency resulting in a better power to weight ratio and performance.

The electronics side of the system is also well served by the company’s high-performance solutions with an overmoulding offering for small actuators, engine and transmission control units and power modules which allow for tighter, tamperproof packaging with a higher production throughput.

With significant demand for these new encapsulation material applications coming from OEMs and Tier 1s in Europe, Sumitomo Bakelite Co., Ltd. will place its newest manufacturing line in Belgium, at its Vyncolit NV subsidiary. Local production capacity and prototyping facilities will enhance the automotive materials offering and the development of bespoke customer solutions.

The new European production line will come online for industrial supply in early 2022, with a production capacity of several thousand tons per annum.

“I am delighted to confirm that we will add dedicated epoxy encapsulation material production at our Ghent facility. This new capacity, positioned close to our leading European customers, broadens our material portfolio and will allow us to tailor encapsulation solutions specifically for each customer,” comments Pieter Vanderstraeten, General Manager and Director, Vyncolit NV.