BRUGGOLEN® TP-H1607 is a proprietary copper based stabilizer package which significantly extends long term mechanical property retention of polyamides to limits unmatched by existing classic copper salt based anti-oxidants. For example, tests demonstrate that BRUGGOLEN® TP-H1607 enables heat stabilization of unreinforced PA 6.6 beyond 5000 hours at 150°C, significantly outperforming conventional copper salt based stabilizers which level off at 3000 hours at this temperature. The extraordinary efficiency of BRUGGOLEN® TP-H1607 offers the opportunity to dramatically reduce copper and halogen content. In PA6.6 at 150°C the copper concentration in the compound was reduced by a factor of more than 5 and still matched the maximum performance level of existing copper salt based products. This capability allows cost savings and opens applications in the E&E sector, such as switch housings and sensors, where a comparative tracking index CTI of 600V is required. Significantly, trials revealed that BRUGGOLEN® TP-H1607 exhibits no greater influence on electro-corrosion than conventional phenolic/phosphite stabilisers used extensively in E&E.

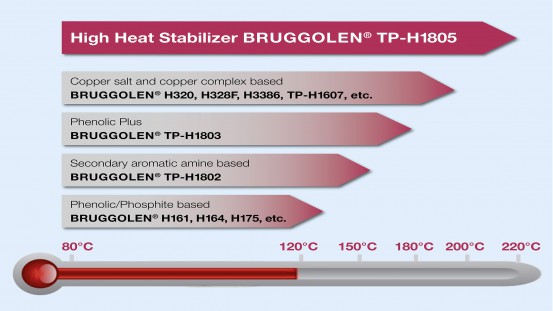

With the new BRUGGOLEN® TP-H1805 Brüggemann has developed an easily processable high heat stabilizer package which stretches the limit for continuous-use temperatures - up to 200°C in the case of glass reinforced PA6 and beyond 200°C for PA6.6. BRUGGOLEN® TP-H1805 does not require prior activation and is also effective at temperatures below 200°C. Thus, compounders have the opportunity to produce cost efficient aliphatic polyamide based materials for border line applications previously reserved for higher priced polyphthalamides or other high performance polymers such as polyphenylene sulfide. In addition, BRUGGOLEN® TP-H1805 may offer the opportunity to substitute, in certain applications, PA6.6 for the less expensive PA6. Both stabilizers are supplied in pellet form and are easy to dose and disperse during compounding.

Dr. Klaus Bergmann, Head of Polymer Additives at Brüggemann: “Our goal is to offer heat stabilizers for polyamides across all temperature ranges and all application areas. With the introduction of these new products we are further extending our portfolio of high-performance stabilizers to provide even more value to our customers.”