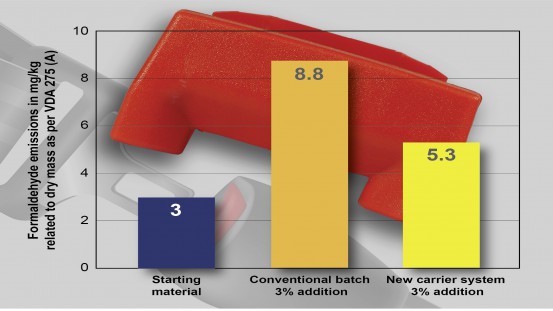

Tests carried out at an independent institute show the efficiency of the adopted measures, based on the example of a conventional, low-emission POM grade, to which a combination masterbatch was added. By switching from the conventional masterbatch to one with optimized color pigment and carrier material, the formaldehyde release was reduced from non-permitted 8.8 ppm to a very good rate of below 6 ppm.

Rudolf Reinhart, Product Manager at Tosaf Color Service, comments: "The carrier material used by us is an easy-flowing, low-emission POM grade from a leading global manufacturer. Customers who use our new masterbatches will always be on the safe side because the emission data from the base polymer are hardly affected." And Sales Manager Andreas Kruschinski adds: "With the consistently high batch-to-batch quality level of our masterbatches, and because of their ease of handling, our new low-emission grades are gaining a growing number of authorizations and are also registering the first series applications for car interiors. SCHAUENBURG Industrietechnik GmbH is one of our pilot customers in this area. In addition, we are experiencing growing demand in all typical POM applications in a wide variety of industries."

The portfolio of low-emission POM masterbatches offered by Tosaf Color Service ranges from grades in standard and customized colors through functional versions, e.g. with lubricants, UV or heat stabilizers, to combination grades with or without a color component. Typical applications beyond automotive interior/exterior parts and conveyor technology include components for office and entertainment electronics, as well as white goods including small and large kitchen devices.