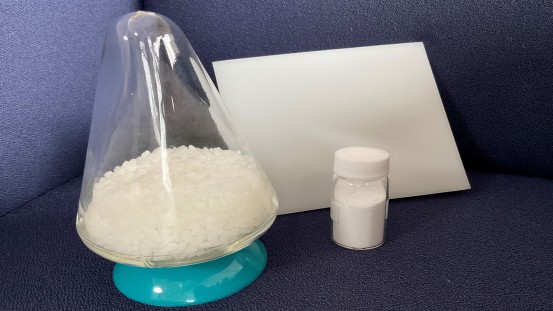

The LUBMER™ UHMW-PE pellet range comprises the highly abrasion-resistant grades L5000, L4000 and L3000 together with LS4140 as an alloy of PA and UHMW-PE. These pellets can be injection molded into industrial parts and extruded into sheets, profiles and hoses using both hot runner systems and conventional tunnel gates. In addition to these base grades, the additives LY1040 and LY4100 can raise the abrasion resistance of many engineering polymers while simultaneously reducing their coefficient of friction. The grades’ opaque light color facilitates the use of color masterbatches.

Used instead of PTFE, the highly dispersible HI-ZEX MILLION™ and MIPELON™ powder grades with particle diameters from 10 μm are suitable for abrasion-resistant, chemically resistant surface coatings or as an additive in compounding.

As Norbert Hodrius, Technical Marketing Director at DREYPLAS, explains: “Our customers have been using Mitsui’s UHMW-PE grades for some time as an alternative to PTFE in applications that do not need its particularly high heat resistance. These polymers are also an attractive alternative from the point of view of sustainability. They can be returned to the PE recycling loop and, being melt-processable and not requiring machining, they generate only small quantities of production waste. We’ll be delighted to provide application advice on further new developments and material substitutions.”

DREYPLAS has also collaborated with a German specialty film manufacturer to develop and bring to market a UHMW-PE film that can be extruded with a minimum thickness of 30 µm. It can be used in place of existing film applications affected by the controversy around PFAS. It is also suitable for thermal insulation in automotive batteries and as part of opaque multilayer films in other applications.