As a global partner to automotive suppliers and OEMs, BASF is committed to advance e-motor development globally while supporting customers locally with R&D, application development and material supply in high, consistent quality. The BASF portfolio for e-motor applications includes tailored plastics for key requirements such as

- EMI shielding

- long service life

- high voltage insulation

- thermal management

- hydrolysis and chemical resistance

- high mechanical load

- weight reduction

- noise, vibration, harshness (NVH) reduction.

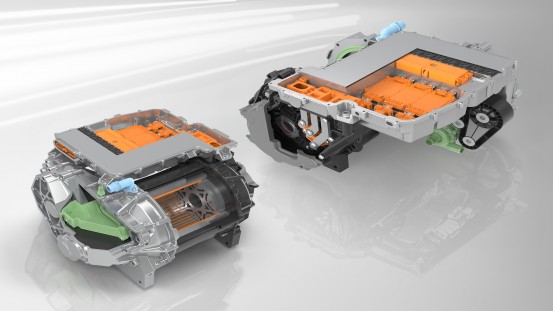

Thus, the size and the weight of e-engines can be further reduced while fostering functional integration and withstanding harsh environments of higher voltages, elevated temperatures and aggressive cooling fluids. This applies to applications like

- housings for motor and inverter

- stator/rotor

- busbars, IGBTs, high-voltage connectors

- slot liners

- components in contact with oils and cooling fluids

- bearing cages

- magnetic encapsulation, engine mounts.

All these parts can work reliably and energy-efficiently thanks to BASF’s diverse material classes of engineering plastics:

- Ultramid® (PA: polyamide)

- Ultradur® (PBT: polybuthylene-terephthalate)

- Ultrason® (PESU/PSU/PPSU: polyarylethersulfones)

- Ultramid® Advanced (PPA: polyphthalamide).

They are characterized by a broad property profile, covering superior features like very good temperature and media resistance, excellent mechanical strength, exact electric compatibility, high purity and tailored flame retardance. The compounds are available in different colors, from colorless to orange and laser-markable black, with short-glass, long-glass or mineral fiber reinforcement, and with various heat stabilizers. The BASF high-performance thermoplastics for e-motor parts can be easily processed in injection molding so that no post-processing is needed. They are weldable and offer a high freedom of part design for different construction needs.