Robotic automation combined with precision measurement for plastic containers will be the focal point for Agr’s display. Featured will be an automated measurement cell that mates Agr’s Gawis 4D measurement system with a robotic handling system for hands-free bottle or preform measurement. The Gawis 4D, Agr’s all-in-one laboratory measurement system, streamlines laboratory measurement operations by performing a multitude of critical dimensional and thickness measurements in one simple operation. With the robotic handling system, up to 128 bottles or preforms can be measured, hands-free, with unmatched accuracy, repeatability and operational throughput. The Gawis 4D features Agr’s patent pending AutoJob™ that provides the ability to create complicated job setups in a matter of seconds.

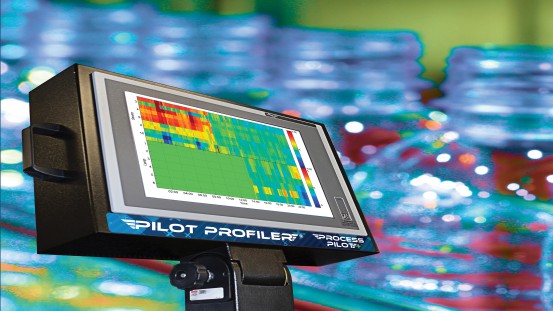

Pilot Vision+™ - Agr’s latest and most powerful in-the-blowmolder vision system. This system is uniquely positioned for the quality management of bottles with high percentages of rPET. Designed to work in conjunction with today’s high-speed reheat stretch blowmolding equipment, the Pilot Vision+ system offers a modular approach to defect detection that works within the blowmolder. The open architecture of this system allows for simultaneous management of up to six cameras, in multiple locations. As part of Agr’s Process Pilot family of products, Pilot Vision+ can be combined with Process Pilot+ for a total bottle management solution, providing the ability to detect random occurring defects as well as manage the process to maintain precise material distribution, even with the lightest and/or most difficult-to-process bottle design.

Agr measurement and processing experts will be available to discuss these products as well as the complete line of process monitoring and quality control equipment available from Agr for the plastic industry.

Agr products are designed to assist container producers, converters and fillers stay competitive while meeting the increased quality demands of today’s changing world. As an industry leader, Agr is committed to provide the plastic container industry with the most technologically advanced products available for quality control and productivity improvement. Additional details can be found on the Agr website at www.agrintl.com.