"With the products we wanted to show the wide range of options available in the field of sustainability and how these can be efficiently produced using both cast film and blown film processes on W&H lines", explained Dr. Lennart Ederleh, Head of Technical Sales Blown Film at W&H. "We worked with over 20 partners from the entire value chain to develop the solutions. We tested downstream processes such as printing and converting in our own technology centers", explained Dr. Torsten Schmitz, Head of Business Unit Extrusion. The sustainable products were first presented to a large audience at the K trade fair 2019.

Monomaterial-Laminates

Monomaterial-Laminates are a trending solution when talking about sustainability. W&H developed two different versions of stand-up pouches, one made of PE and one made of PP. Thanks to Machine Direction Orientation (MDO), the VAREX II blown film line can produce stand-up pouches from 100% PE material that offer the same functionalities as conventional films based on a material mix of PET-PE. Both the MDO-PE film with 25 µm and the PE sealing film with 110 µm can be produced on the same line. The edge trimming of the MDO-PE film is regranulated and integrated into the production process of the sealing film. On the FILMEX II cast film line, W&H produced a stand-up pouch made of all-PP. The laminate structure consists of 20 µm BO-PP film and a 60 µm Cast-PP film with an integrated thin, recyclable barrier coating.

Recyclable high barrier film

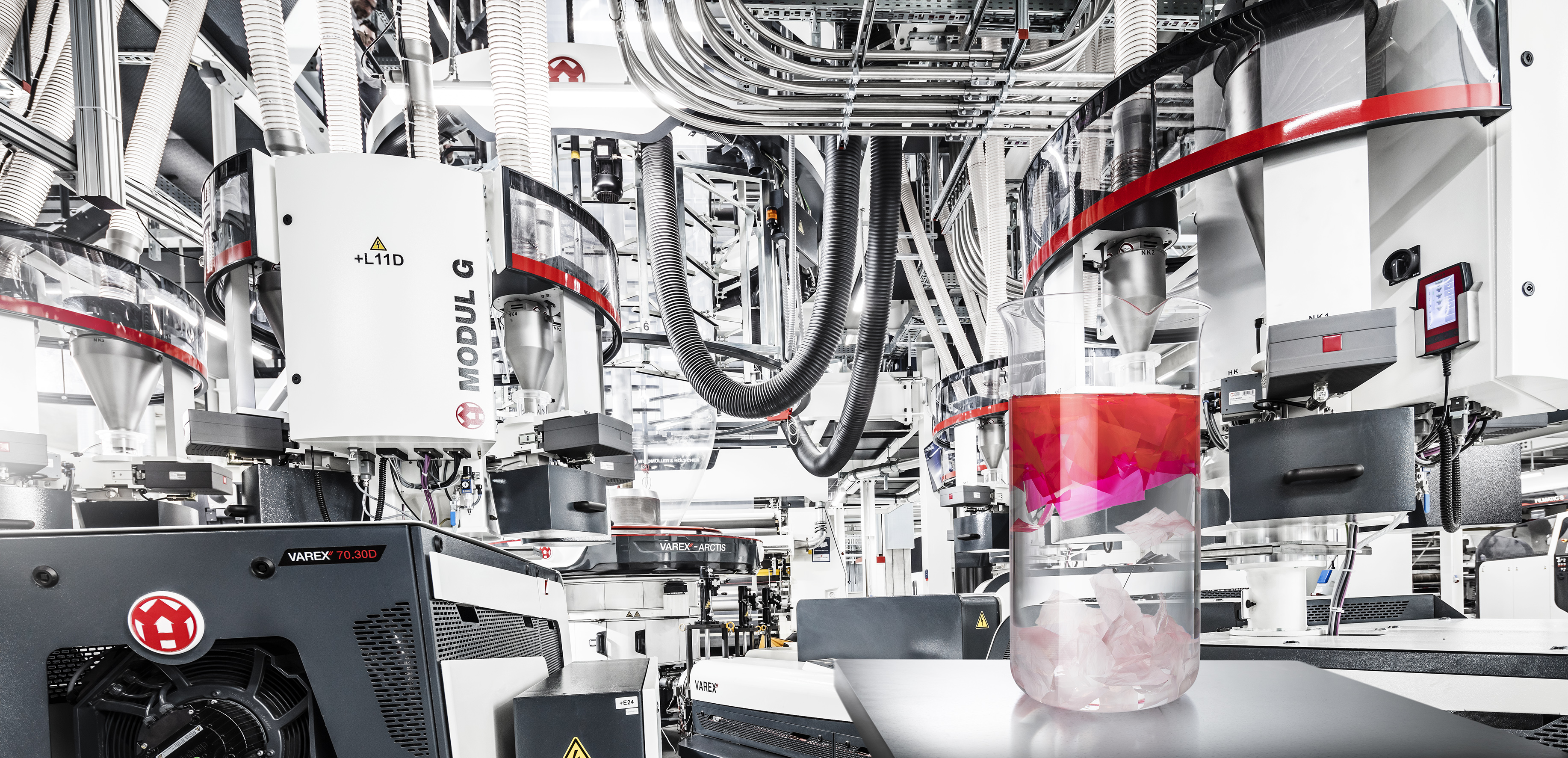

The recyclability of high barrier films was tested by using thin layers of a water-soluble barrier polymer. The VAREX II blown film line offers the required excellent melt distribution for this packaging solution, in which the conventional EVOH for the oxygen barrier is replaced by BVOH G polymer. Only with the 11-layer technology of the VAREX II can the varying requirements of the individual raw material classes be optimally met. For the recycling process, the film is shredded and washed in water. The BVOH layers dissolve and the pure PA sinks to the bottom, while the PE flakes float on top. This separation enables the pure polymers to be recycled.

Use of recycled material

W&H also tested packaging solutions in which recycled raw materials are used. Bottle shrink films with 20% post-consumer recycled material were produced on the OPTIMEX II blown film line. Shrink films with 30% post-industrial recycled material were made with the VAREX II. The films offered the same shrink properties and mechanical properties as conventional film based on virgin material. “The sample products are the basis for intensive discussions with our customers about which ideas there are and with which technologies they can be implemented”, explains Ederleh.